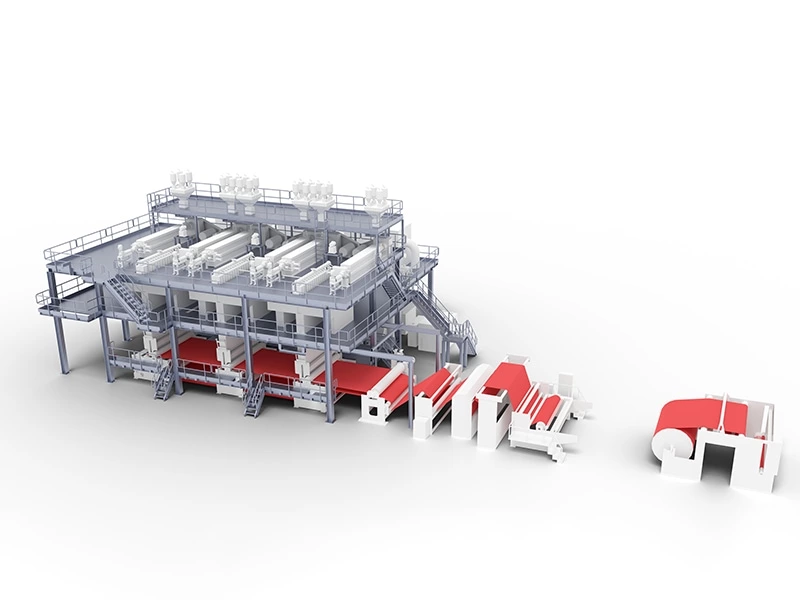

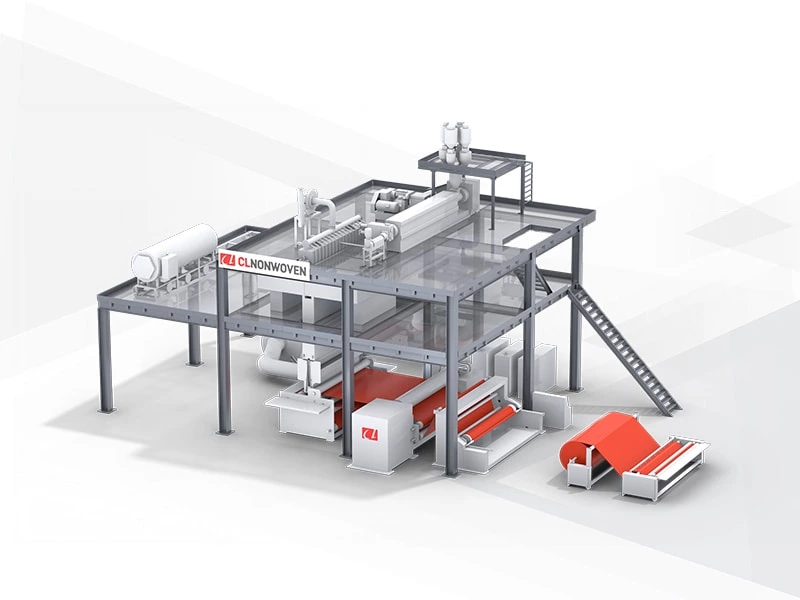

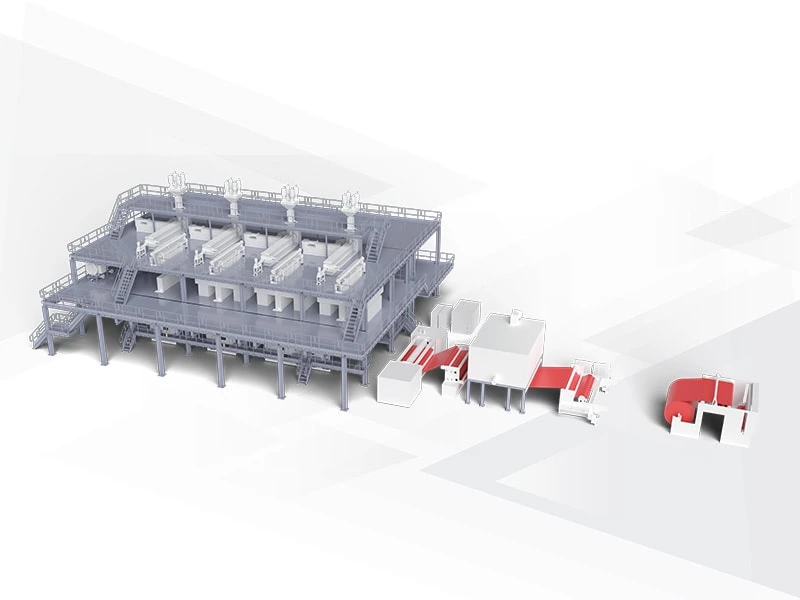

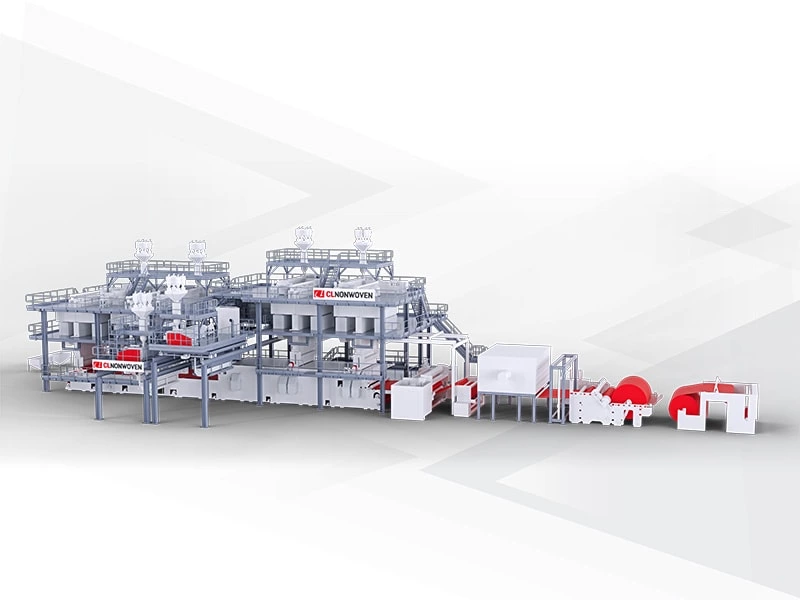

Bico Nonwoven Fabric Line

In 2011, CL designed and manufactured China's first Bico production line. The Bico nonwoven fabric produced by this line is primarily used in hygiene products, such as diapers and sanitary napkins, as well as in various industrial applications. These fabrics offer exceptional softness, strength, making them ideal for high-performance requirements.

Bico Nonwoven Fabric Making Machine Technical Specification

This Bico Nonwoven Fabric Making machine is mainly used for producing spunbonded nonwoven fabric made from PET and PP as primary materials. It involves a single-head, bicomponent spinning system with thermal bonding.

2.Equipment Performance Requirements and Main Technical Parameters

2 .1 Equipment Performance Indicators:

2.1.1 Weight Range: 18-200 gsm

2.1.2 Finished Fabric Width: 3200 mm (after trimming)

2.1.3 Production Line Speed: Maximum mechanical speed: 150 m/min; Maximum process speed: 100 m/min

3. Main Technical Parameters of Production Line Components:

3.1 Spinning System Main Equipment

Spinning Width: 3400 mm (subject to actual delivery)

3.1.1 PET Chip Drying and Crystallization System (1 set)

Crystallizer Output: 400 kg/h

Dryer Output: 400 kg/h

Secondary Conveying Output: 400 kg/h

3.1.2 PET Masterbatch Drying System (1 set):

The masterbatch is manually added to the drying device for masterbatch drying treatment.

Dryer Output: 100 kg/h

3.1.3 PET Masterbatch Metering and Mixing Feeding System (2 sets):

Suction, Metering, and Mixing Capacity: Maximum 50 kg/h (Normal operation: 20-40 kg/h)

Component One: Addition ratio 0.05–0.1%

Component Two: Addition ratio 0.05–0.1%

Metering Method: Screw extrusion metering

Maximum Components: 2

3.1.4 Screw-Type Four-Component Suction, Metering, and Mixing Feeding System (1 set)

3.1.4 PET Screw Extruder (1 set)

3.1.4 PP Screw Extruder (1 set)

3.1.5 Vertical Sleeve Melt Filter (2 sets)

3.1.6 Metering Pump and Drive (2 sets)

3.1.7 Spinning Box (1 set)

3.1.8 Monomer Suction Device (1 set)

3.1.9 Side Blowing Device (1 set)

3.1.10 Drawing Device (1 set) (imported)

3.1.11 Drawing Fan (1 unit) (imported)

3.2 Web Formation Machine

3.2.1 New Web Formation Machine (1 set)

Web Performance (1 set)

Web Correction Device (1 set)

Drive System (1 set)

3.2.2 Two-Roll Thermal Calender (1 set)

Production Process Speed: 150 m/min

3.2.3 Winder (1 set)

3.2.4 Slitter (1 set)