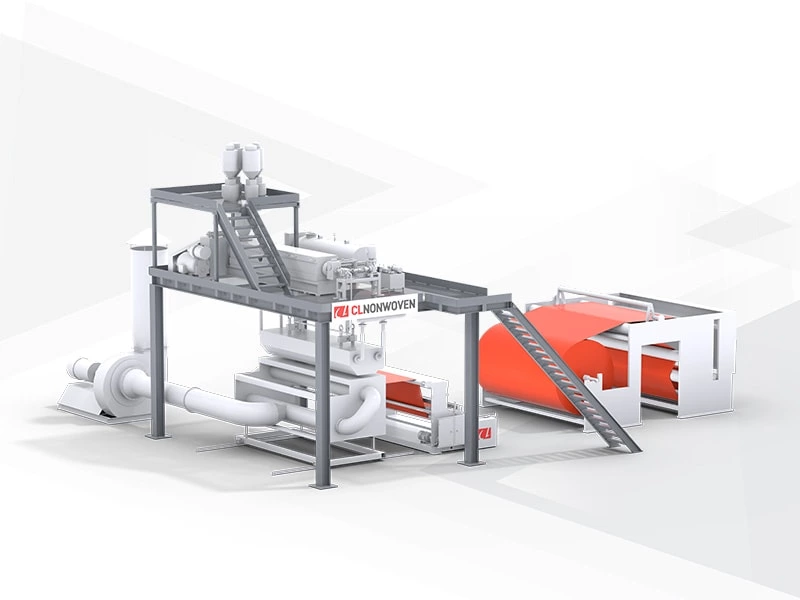

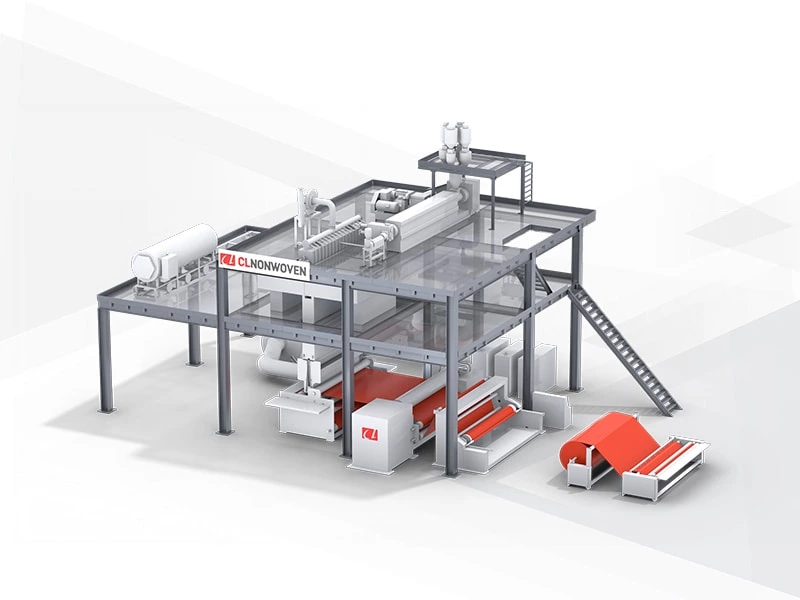

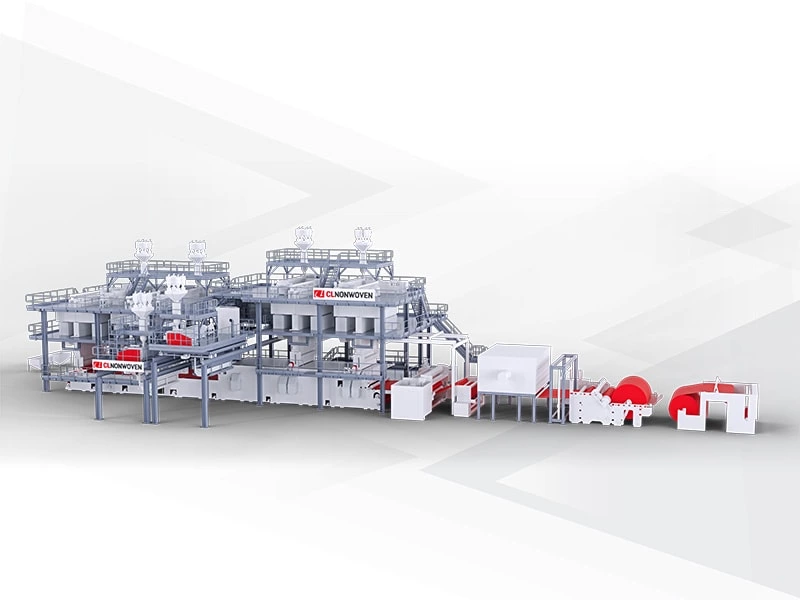

Meltblown Nonwoven Fabric Line

Meltblown nonwoven lines are a crucial part of the nonwoven fabric production industry, known for their ability to produce extremely fine fibers and high-performance materials. it have a wide array of applications due to their unique properties, including high filtration efficiency,absorbency,and barrier performance.

Meltblown Nonwoven Fabric Making Machine Technical Specification

Production process

PP chip tank -> Air transport device -> Extruder melting -> Filtering -> Spinning -> Hot air -> Web form -> Winding.

Electrical control system and other machine main parts

1. Feeding system (1set )

Maximum absorption capacity of main material: maximum 300kg/hr

2. Extruder (1set )

Capacity: maximum 200kg/hr

3. Hydraulic filter (1set )

Hydraulic screen changer, adopt electric heating.

4. Meltblown head (1set )

Each spinneret can distribute the melt symmetrically and under constant pressure.

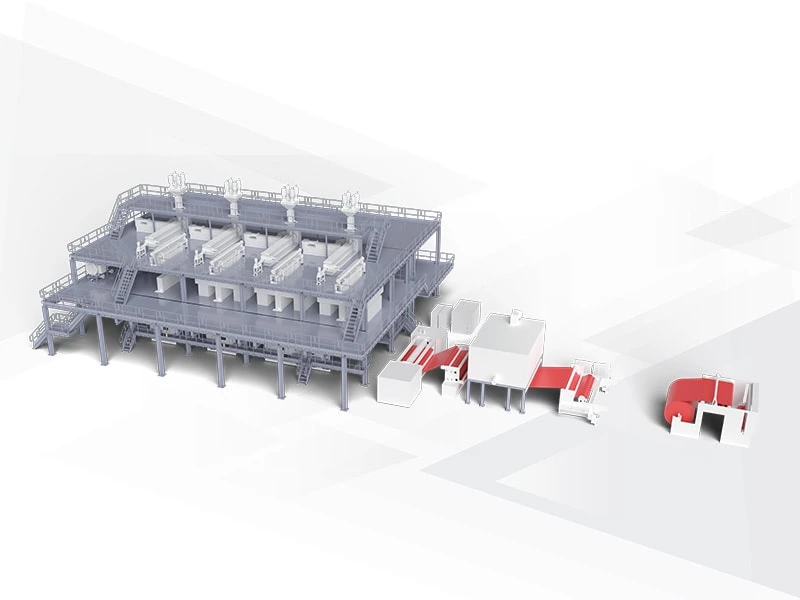

5. Steel platform structure (1set )

Required steel structure for die, cooling, stretching, web forming and others device, including operational platform, guard bars, stairs and so on. The platform is designed and installed by the seller.

6. Web former. (1set )

Type of web former: cylindrical suction duct

7. Winder with on line cutter (1set )

Winder can set the length, automatic doffing. Winder diameter can reach 1m.